Multi-spindle screw machines are the most productive lathes in the world. Unlike a single-spindle lathe, Davenport Machines provide five working spindles. Allowing users to see significant productivity gains for high volume part allotments. Our various machine platforms allow us to provide solutions for almost any industry.

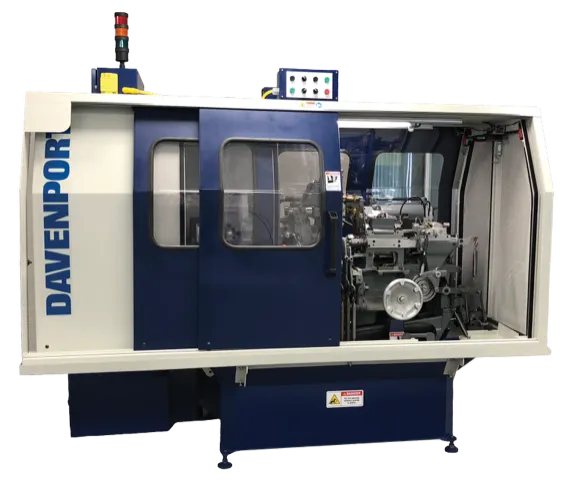

Hybrid Machine

The Hybrid has the mechanical dependability of our multi-spindle machines while incorporating the ease and accuracy of CNC machines.

Model B

Since 1900, the Model B has been the most economical multi-spindle automatic screw machine in the world.

Chuckers

Multi-spindle automatic screw machine designed to complete secondary operations on preformed blanks. Now available with the HP High Precision revolving head.

- Precision Tolerances

- Flexibility

- Reduced Setup Times

- CNC Interface

- Machine Aerospace Alloys

- Single Point Capabilities

- Eliminate Secondary Operations

- Fast Cycle Times

- Ability to complete simple or complex parts

- Small Footprint

- Time Tested and Proven for over 130 Years

The Chucker machine is a versatile high production machine used to complete secondary operations.

- Legendary Davenport speeds

- Available with HP High Precision Revolving Head

- Can be interfaced with automated loading equipment

- Adaptable for a variety of part applications

One-Inch Model B

The Davenport One-Inch Model B Machine will manufacture larger parts up to one inch diameter. The Inch Machine has a smaller footprint and is more cost effective than other larger multi-spindle machines.

Our Machine Expertise

Over 14,000 Davenport machines have been deployed globally. Have you ever wondered why? Davenports are the fastest multi-spindle machines on the market. They have the smallest footprint, and are the most versatile machines in their class.

With unparalleled support and service, it’s no wonder we have been in business for over 130 years.

Contact us today to learn if Davenport machine is right for your application.