We understand the value of a machine remanufacture and that you have many options when it comes to reconditioning a worn-out Model-B. Some of our longest running customers operate dedicated rebuild shops within their own facilities, where their maintenance departments recondition machines in between emergency repairs on production equipment. Others send their machines to one of the many independent Model-B rebuilders across the country, many of which partner with Davenport Machine to supply replacement parts for components that have outlived their useful life. Then there are shops that “have a guy,” often a retired employee, working out of a pole barn in his backyard. Each company must determine which option is right for them.

However, for shops whose customers demand the highest quality screw-machine parts, one choice stands out: sending your machine back to Davenport for an OEM Certified remanufacture.

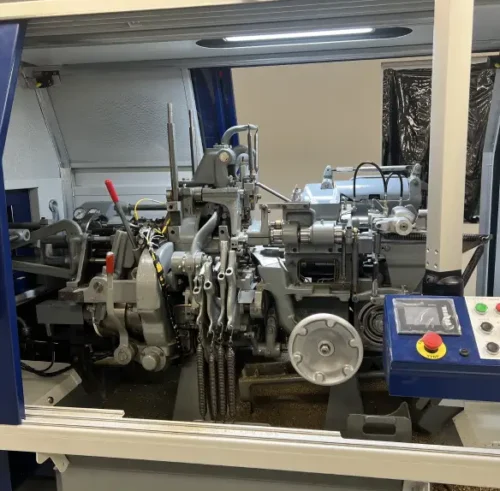

There are several key advantages to choosing a certified OEM to remanufacture your machine. First, we rebuild your machine using the same equipment and tools as a brand-new machine. We have invested in state-of-the-art production and inspection equipment to ensure that each Davenport machine is perfectly aligned and that every component fits as intended. From high-accuracy 5-axis mill-turn machining centers to a scanning-head CMM capable of scanning an entire bed casting, Davenport’s capabilities for precision are unrivaled among machine rebuilders.

Advantages of an OEM Rebuild

Further advantages can be found in Davenport innovations. We upgrade every remanufactured machine with the latest designs for critical-to-function mechanisms, enhancing accuracy, longevity, and serviceability. If we developed it for our new machines, it can usually be retrofitted to your remanufactured machine, as well. Our new Needle Bearing Locating Lever offers wear-free precision indexing, while improved starting and high-speed clutches ensure more consistent cycle times. The new BP-600 brake assembly and 5080-131-3-SA wear-plate roll-away clutches reduce the need for frequent machine adjustments.

Let’s not forget the needle-bearing style tool arm studs and back-countersink levers, which address some of the most common chatter-causing issues on these machines. These recent enhancements—and many others—are automatically included when you choose Davenport to remanufacture your machine. You can also choose from a menu of à la carte upgrades, such as HP Heads or peripheral equipment like quiet electric coolant pumps, motor-driven chip augers, cartridge-style coolant strainers, or even modern PLC-based electronic controls.

Perhaps the most important advantage of an OEM Certified rebuild is the people behind the work. Our Assembly Techs have a combined 75 years of experience building, repairing, and remanufacturing Model-B machines. They are called out into the field whenever a customer faces a repair that is too daunting to tackle in-house, or if an issue proves difficult to diagnose. They have seen it all, and very few things surprise them. They are supported by a full staff of engineering and manufacturing specialists who can evaluate any issues that arise during the process and implement solutions to get your machine back up and running—better than new. When they take apart and reassemble your machine, you can rest assured that the work is executed to OEM standards, with Davenport standing behind it with a full new machine warranty. No other aftermarket rebuilder offers that level of commitment to your satisfaction.

If your high-hour production equipment is no longer meeting your precision and productivity goals, consider OEM remanufacturing with Davenport Machine. You won’t just get a machine that works like new; your machine will work better than when it was new.