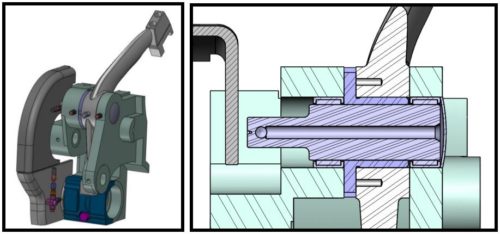

This is an update to our standard 5080-34-1-SA Locating Lever Assembly. The new assembly features precision needle bearings in place of the older tapered bronze bushing design. The old design required intermittent adjustments in order to keep the locating lever stud tight. If the bushings weren’t adjusted correctly, the revolving head index would vary, or the locating lever will pick-up and seize. The new needle bearing design eliminates the need to make any adjustments, and can be retrofit on all Davenport screw machines. The bearings are preloaded to work with a ZERO CLEARANCE design and are now connected to the machine’s automatic lubrication system, to maximize machine precision and minimize time lost to maintenance. The assembly is easy to install, and is complete with the Stud, Bearings, Nuts, Coolant fittings/manifold, and sleeves.

New Features:

- Increased rigidity and precision

- Eliminates adjustment of stud/bushings

- Connection to lubricant system to flush bearings for longer life

- Can be retrofitted to ALL Davenport machine models

CJWinter and Davenport Machine OEM parts are constantly being redesigned to maximize the value to the Customer. Any parts supplier can sell you yet another replacement part for your problem. Let the team at Davenport Machine supply you with a cost effective solution to it instead. Contact your local distributor, or

call us directly at 1-800-344-5748 and ask about our many new and improved products that will help put profits back where they belong… in your pocket.

If you found the above information valuable, take a look at our “Did You Know?” Engineering Bulletins that allow you to stay up-to-date with Davenport News as well as announcements about our attachments and replacement parts. The bulletins have proven to be a valuable resource for anyone who uses our product.