Table of Contents

ToggleWith a legacy spanning over 130 years, there is no question our company has seen tremendous change in manufacturing. In today’s ultra-competitive manufacturing world, time seems to always be of the essence.

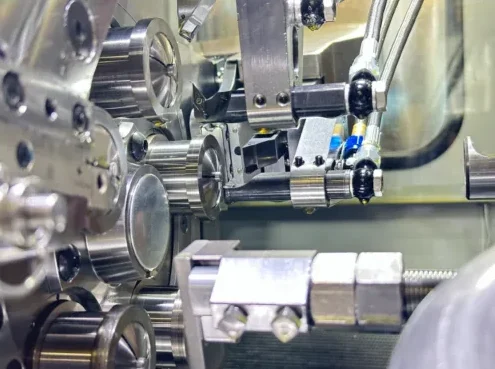

Innovative Tooling System for the Hybrid CNC Platform

With this in mind our team of engineers developed a tooling system for our Hybrid CNC platform to alleviate many of the pain points our customers feel with traditional machines. While incredibly productive, it is no secret mechanical multi-spindles can be time-consuming to set up and change over. We have seen many customers alleviate this by adopting the Hybrid, reducing downtime, and shipping more quality parts out the door.

Benefits of the Modular Tooling System

One major benefit of the Hybrid Machine is our new modular tooling system, meant for quick and seamless setup. This starts with our form tool holders – available in 13, 20, and 24mm – the 1st and 2nd position holders utilize our latest dovetail interface technology. The holders are fully adjustable for center height and taper. They utilize standard carbide inserts that can be purchased from any major carbide manufacturer. Inserts can be swapped out quickly, and holders can be adjusted faster than traditional circular form tools or Davenport’s previous iterations of dovetail holders. With improvements to the machine’s rigidity and overall accuracy, you can form features with tolerances that previously required shave tool operations. A shave tool has never been utilized on a Hybrid Machine. This saves operators significant time during setups, cutting into downtime.

Enhanced Flexibility with CNC Cross-Slides

CNC cross-slides in 3rd and 4th can use standard off-the-shelf turning, grooving, or threading inserts, and can be adapted to hold boring bars for ID undercuts and grooving, as well as round shank tool holders for forming. The setups of these CNC slides allow far more flexibility to move away from specialized tooling and can allow you to start a new job in a pinch with standard tools. 3rd position is a 3-axis slide that can utilize either a two-tool live tooling station for milling-type operations, or a dual stick tool mounting block to provide additional turning flexibility. These compact tool holder configurations allow for tool holders to be swapped much faster than the old-school bulky bolt-on attachments developed for the Model B and other mechanical machines.

Efficient Tool Changes with QCT Technology

End working spindles on the Hybrid almost exclusively utilize our QCT (Quick Change Toolholder) technology. With a series of ER collet sizes, these QCT holders can be

easily pre-set outside the machine, making tool changes a breeze. You can add and remove these holders with a quarter turn and a set screw. Easily adjustable and faster changes lead to significant time savings during setup and in production.

Advantages of the High-Pressure Coolant System

The Hybrid also comes standard with a 1,000 PSI ChipBlaster high-pressure coolant system. Allowing you to get high-pressure coolant right to the tooltip. This system ensures longer tool life and better machine performance. This is a major reason why the Hybrid Machine can handle the toughest high-temp alloys.

Significant Time Savings and Advanced Technology

The Hybrid Machine features the latest and greatest technology from Davenport Machine, saving you precious time on changeovers and specialty tooling. It has shown on average that setup time can be reduced by nearly 50% over traditional mechanical machines.

Check out our 25-minute changeover video.

Contact us or visit the Hybrid Machine page to learn more to learn more.