Discover the revolutionary capabilities of the Davenport Hybrid Machine, a groundbreaking solution in the realm of multi-spindle CNC machines. Renowned for its adaptability, the Davenport Hybrid is your go-to for a broad range of milling and cross-drilling applications.

Our expert engineers have dedicated themselves to crafting the most versatile and user-friendly attachments, ensuring your operations on the Davenport screw machine are seamless and productive. The innovative dovetail technology streamlines tool changes, dramatically reducing downtime during changeovers.

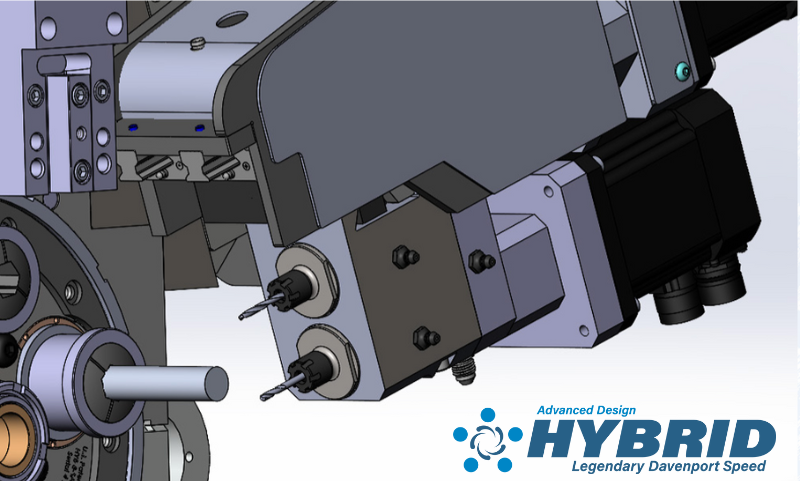

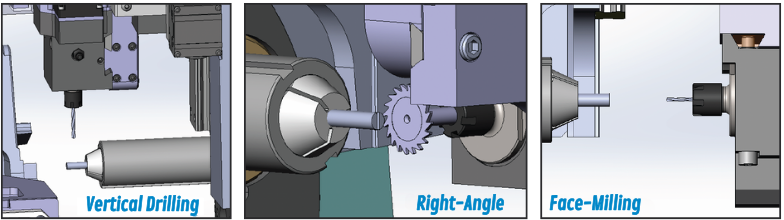

The 3-axis, multi-purpose CNC slide is a pivotal 3rd position upgrade for your Hybrid machine. The dual spindle milling head allows for two tools to be mounted, providing the capability for combo operations to be completed on one tooling slide. The dove-tail mounting interface makes this slide easily adaptable for our turning tool holder for single point turning and threading operations.

The Hybrid’s sub-spindle milling attachments open new horizons in machining versatility. From flat generation to cross hole drilling and slot cutting, these compact attachments maximize the functionality of your multi spindle lathe. The design allows for two additional tools on the pick-off spindle, enhancing your machine’s capabilities, including rigid tapping, drilling, and OD/ID grooving.

Join the ranks of satisfied users leveraging the full potential of our latest technology.

Contact us and download our brochure today to explore the revolutionary milling and cross-drilling possibilities of the Davenport Hybrid.