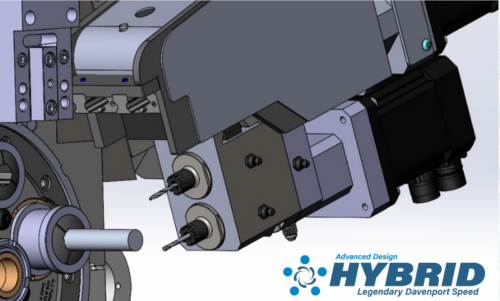

Exclusive First Look at Davenport Machine for PMTS 2025

It is hard to believe PMTS 2025 is right around the corner and we are already two months into 2025. The year has already brought many changes; a new administration, a return of brutal winters for those of us in the Northeast, and a manufacturing industry that looks to be