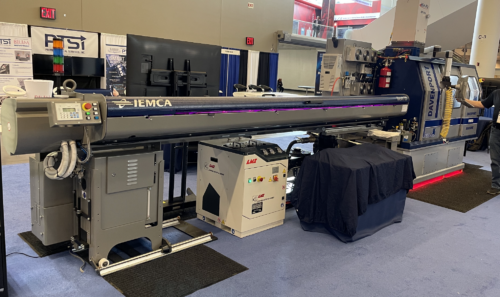

Speed, productivity, and efficiency through automation are some of the most important objectives that come to mind when discussing multi-spindle machining. 2023 has marked some incredible enhancements to our technology at Davenport in advancing these outcomes, and one of the most important of these is the NEXT 25 bar loading system for the Davenport Hybrid Machine. Through a partnership with Bucci Industries, manufacturers of the IEMCA line of bar loaders, Davenport machines will now be able to reach even higher levels of productivity and efficiency.

Headquartered in Faenza, Italy, Bucci has been at the forefront of innovations in machine tools, automated assembly, and bar loaders for over 80 years with facilities located throughout the world. Since 1961, its line of IEMCA bar loaders and bar feeders has been a leader in loading technology, and its products have been adopted by virtually all brands and models of lathes and multi-spindle machines.

In a collaboration with IEMCA, Davenport has introduced the NEXT 25 bar loading system to our Davenport Hybrid Machine, with development work underway to extend this to the traditional Davenport Model B. The efforts from both parties to make this project a success have been outstanding, and both Bucci and Davenport look forward to working together for years to come. “This has been one of the most rewarding projects that Bucci has undertaken in recent years. The knowledge of the application and the professionalism that we have experienced working with the staff at Davenport has been outstanding”, states Ray Varady, GM of Bucci, USA.

The NEXT 25 loader is a proven technology with a strong track record of success in the industry, primarily based on its straight-forward operation and dependable nature. Because of these attributes, it is an optimal fit for the Davenport Hybrid. “The backbone of Davenport’s legacy is speed and mechanical dependability. The industry success of the NEXT 25 loader makes it a natural for fit for Davenport’s various machine models and customer applications…” Ryan Bavineau, Outside Sales, Davenport Machine, INC.

Equipping an IEMCA NEXT 25 bar loader with the Davenport Hybrid will help manufacturers see significant productivity enhancements. Without the need to stop machining so as to load bars through the stock reel, the IEMCA NEXT 25 will allow material to support longer run times without interruption, thus enabling valuable labor to concentrate on more pertinent machine operations.

The NEXT 25 is compatible with the Davenport Hybrid, Davenport HP and Davenport Model B machines (Model B adaptation kit will be released shortly). Although individual results will vary, initial indications are that productivity gains of between 12% – 25% could be expected through the use of a loader when compared to real-world manual stock-loading environments. “The NEXT 25 will be a game changer for our customers, not just on the Hybrid, but across all of our machine platforms.” Jim Schreiner, General Manager, Davenport Machine, INC.

The Davenport Hybrid, paired with the IEMCA Next 25 will provide longer, continuous machining, more parts out the door and an enhanced return-on-investment.

Contact us today to learn more about equipping an IEMCA NEXT 25 to your Davenport!